Fuel Injector Cleaning & Flow Testing Services

Please fill out theService Order Form with your name, phone number, address, and email for return tracking. Payment is not required upfront; we will contact you once the job is complete to arrange payment and shipping. Send your fuel injectors to our Rockville Centre, NY location for fast service. We use only the highest quality components, including filter baskets, o-rings, spacers, and seals. Your injectors will be fully assembled and ready for installation upon return. For assistance, call us at 516.442.4707.

- Most common MPI Top Feed Injectors Auto, Marine - $22.50

- Side Feed & Optimax Gas - $25.00

- OptiMax Air - $35.00

- GM Throttle Body - $75.00 a pair with orings filters and gaskets

- GDI Direct Fuel Injectors - $25.00

- Hose Feed Injectors - $30.00

We do not service Diesel E-tec or index injectors(piezo)

Mail Injectors with Service Order Form To:

SouthBay Fuel Injectors

566 Merrick Road Suite 3

Rockville Centre NY 11570

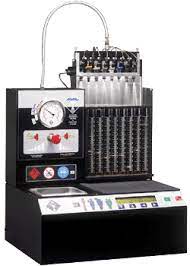

Off-the-car fuel injector cleaning is essential. Quick fixes with "out-of-the-can" cleaners can be ineffective and potentially damaging, as they might introduce contaminants into the fuel injector's fine filter. SouthBay Fuel Injectors restores full functionality to injectors by replacing all essential components such as o-rings, pintle caps, spacers, and filters, providing this service at a lower cost than purchasing new or rebuilt injectors. Utilizing the latest ASNU Classic GDI fuel injector Flow Benches, SouthBay's proven process effectively returns fuel injectors to their original OEM condition.

- Benchmark test injectors

To accurately compare before and after results, establishing a benchmark is essential. Injectors are placed on the test bench in their received condition upon arrival at our shop. We test for leakage at 80 psi and conduct both static and dynamic flow tests. All findings are recorded and will be included in your service report.

- OHM test injectors for maximum electrical performance

One effective method to diagnose faulty injectors is to utilize a multi-tester, also known as a multimeter. By testing for continuity with the OHM setting, you can determine whether the injector's connection is within normal parameters or if it has failed and become inoperable.

- Remove internal filters, O-rings and pintle caps

External parts and filters tend to deteriorate with time and extreme operating conditions and stress from everyday use. Never reuse these parts.

- Clean external injector body ultrasonically

Three-step ultrasonic cleaning uses cavitation bubbles induced by high-frequency pressure (sound) waves to agitate a liquid. This process applies intense forces to dislodge contaminants from substrates like metals, plastics, and ceramics, and can penetrate blind holes, cracks, and recesses. The objective is to thoroughly remove all contamination that is firmly attached to or encased within solid surfaces. Our machinery employs ultrasound (usually between 20–400 kHz) and an appropriate cleaning solvent.

- Clean fuel injector internally with ultrasonic technology

The same technology used for external cleaning is applied to the internal cleaning of injectors. During this process, the injector is subjected to pulsing within a heated ultrasonic bath set at varying intensities, ensuring the effective removal of any lingering contaminants from the injector's internal components.

- Flow test to verify proper atomization and injector flow characteristics

The injectors are reinstalled on the test bench to verify their flow rate, spray pattern, and leak down. Initially, they are tested statically to assess size and flow comparison. Then, they are subjected to dynamic flow testing on a computer-controlled test bench, which includes sequentially firing the injectors from 600 to 10,000 RPMs and cycling through pulse widths from 3ms to 12ms. This process simulates various throttle positions and driving scenarios. If the injectors do not meet specifications at this point, the cleaning process is repeated.

- Use industry standard fuel injector calibration fluid

We use only the highest quality calibration fluid for our testing equipment to ensure accuracy. This fluid closely mimics gasoline without being actual gasoline. Specific gravity is the ratio of the density of a substance to the density of a reference substance, which is gasoline in our context. Apparent specific gravity is the weight ratio of a given volume of the substance to the same volume of the reference substance. This, along with the correct temperature, is crucial for achieving not just a good tune-up but an excellent one. Our tests are performed with SouthBay's Calibration Fluid at 20°C (±1°C), 3.0 Bar (±0.01 Bar), and 13.8V (±0.05VDC), using a saturated driver and RC cutoff. The injector flow rates are calculated by comparing tests with SouthBay's Calibration Fluid (0.741 g/ml) against the U.S. EPA emission test gasoline 40CFR86.113 (0.735g/ml).

- Reassemble Injectors

All components removed prior to the external cleaning process are substituted with new, OEM parts designed specifically for your injector.